The New York Times

Governor Maura Healey and Lt. Governor Kim Driscoll

Engineering News-Record

The funding from the Department of Energy’s Office of Clean Energy Demonstrations (OCED) will accelerate construction of Sublime’s first commercial manufacturing plant in Holyoke, Mass., while expanding economic opportunity for the community, a former paper manufacturing hub

SOMERVILLE, Mass.–Sublime Systems — which is advancing a fossil-fuel-free, scalable, drop-in replacement for traditional cement in concrete — was selected by the U.S. Department of Energy (DOE) Office of Clean Energy Demonstrations (OCED) to begin award negotiations for up to $87 million in Bipartisan Infrastructure Law and Inflation Reduction Act funding as part of the Industrial Demonstrations Program (IDP). Sublime’s First Commercial Electrochemical Cement Manufacturing project was selected as one of 33 projects across more than 20 states to receive up to a total of $6 billion to demonstrate commercial-scale decarbonization solutions needed to move energy-intensive industries toward net-zero while strengthening local economies, creating, and maintaining high-quality jobs, and eliminating harmful emissions that jeopardize public health. Sublime had previously announced it selected the site for its first commercial manufacturing facility in Holyoke, Mass., a city that once manufactured most of the paper in the United States.

“Access to sufficient capital for industrial-scale demonstrations is the single biggest obstacle preventing breakthrough innovations from reaching the scale humanity needs to combat the climate crisis,” said Sublime Systems CEO and Co-Founder Dr. Leah Ellis. “The Department of Energy has cleared this obstacle through funding from OCED’s Industrial Demonstrations Program, embracing its unique role in supporting the deployment of the decarbonized technologies of tomorrow. We look forward to collaborating with them on funding our first commercial manufacturing scale-up, which will ship our clean cement while creating meaningful economic opportunities for the surrounding community.”

OCED applicants were required by the DoE to submit Community Benefits Plans (CBPs), in which they must show that they will engage communities and labor, create quality jobs, and prioritize economic and environmental justice for disadvantaged groups. Sublime was guided to Holyoke through screening tools created by Justice 40, an initiative that directs 40% of the overall benefits of certain federal investments to flow to disadvantaged communities.

Sublime expects to create hundreds of jobs during the construction phase of the project and 70-90 ongoing roles once the plant is operational. The company has signed a strategic partnership agreement with the United Steelworkers (USW) — which represents approximately half of unionized cement workers in the U.S. today — focused on operational positions in the Holyoke plant. Sublime has also signed Memoranda of Understanding to negotiate project labor agreements with the region’s building trade unions, for the construction phase of the project.

“The USW congratulates Sublime on being selected to receive this groundbreaking funding from the Department of Energy,” said USW International President Dave McCall. “We look forward to continuing our partnership and building the skilled union workforce necessary to advance Sublime’s breakthrough clean cement manufacturing technology.”

Bolstering Sublime’s CBP is a collaboration with the Smithsonian Science Education Center (SSEC). Through early and frequent engagement with Holyoke stakeholders, it became clear that there is a shared community goal of building up an educational ecosystem that prepares residents to capitalize on high quality career opportunities in STEM. The OCED selection includes funding to bring SSEC’s educational programming resources to bear in support of that goal.

“This support facilitates the Smithsonian Science Education Center’s ability to offer programming to the Holyoke Public Schools that will enhance students’ understanding of complex global issues such as decarbonization and equip them with the skills and knowledge necessary to become agents of change,” said Dr. Monique M. Chism, Smithsonian Under Secretary for Education. “Programs such as this enable students to grasp firsthand how advanced technologies, developed in their own backyard, support global efforts to fight climate change — and the actions they can take to promote life on a sustainable planet.

Cement is the key ingredient in concrete — the most consumed material on Earth after water — and its production is currently responsible for 8% of global CO2 emissions. Today’s ordinary portland cement (OPC), is made with a 200-year-old process that thermally decomposes limestone, a rock that is nearly half CO2 by weight, in fossil-fueled kilns running at temperatures as high as 1450°C.

Sublime launched in 2020 with a mission to have a swift and massive impact in cleaning up production of this essential building material. It has since scaled its electrochemical cement manufacturing to a pilot capacity of 250 metric tons per year (TPY). The Holyoke first commercial facility will open as early 2026 and will produce up to 30,000 TPY of Sublime Cement™, without the fossil fuel pollution — such as NOx, SOx, mercury particulates, and kiln dust — that are often characterized by industrial growth.

“Spurring on the next generation of decarbonization technologies in key industries like steel, paper, concrete, and glass will keep America the most competitive nation on Earth,” said U.S. Secretary of Energy Jennifer M. Granholm. “Thanks to President Biden’s industrial strategy, DOE is making the largest investment in industrial decarbonization in the history of the United States. These investments will slash emissions from these difficult-to-decarbonize sectors and ensure American businesses and American workers remain at the forefront of the global economy.”

Holyoke Mayor Joshua A. Garcia said, “Thanks to the dynamic interplay between federal, state, and local policy, we are ushering in a new era where economic opportunity and fighting climate change go hand in hand — both in our community and so many similar former industrial hubs throughout the United States.”

Massachusetts Governor Maura Healey, who has proposed a $1 billion, 10-year investment to make the state a leader in climatetech, added, “Sublime represents the tremendous potential the climatetech industry has to transform and grow Massachusetts’ economy – from its beginnings at an incubator to its expansion in Holyoke for manufacturing. Sublime’s ingenuity, boosted by state and federal funding, is creating good-paying jobs and boosting our economic competitiveness. We congratulate Sublime on this exciting achievement and will continue to advocate for our Mass Leads Act to replicate this success with other climatetech companies.”

Dr. Emily Reichert, CEO of the Massachusetts Clean Energy Center, added, “I’ve been able to see Sublime Systems grow from the startup space at Greentown Labs to its latest expansion to manufacture its low-carbon cement product in Holyoke. The Healey-Driscoll Administration is working to make Massachusetts the climate innovation capital of the world. We are proud to see the solutions to climate change being built across the Commonwealth of Massachusetts. Sublime Systems shows us this is possible.”

Sublime has already secured capacity reservations for more than 45,000 tons of the Sublime Cement™ that will be produced out of Holyoke. Email partnerships@sublime-systems.com to inquire about a reservation for your construction projects or holyoke@sublime-systems.com to learn more about our plans there.

About Sublime Systems

Sublime Systems is on a mission to have a swift, massive, and enduring impact on global CO2 emissions by decarbonizing cement. Unlike net-zero solutions that rely on carbon capture or credits, Sublime’s fully electrified, “true-zero” approach avoids the industry’s legacy fossil-fueled kilns and limestone feedstock. Sublime’s electrochemical process instead extracts reactive calcium and silicates from an abundance of raw materials at ambient temperature, to make ASTM C1157-compliant Sublime Cement™, a drop-in replacement for ordinary portland cement in concrete. Sublime was founded at MIT by Dr. Leah Ellis and Prof. Yet-Ming Chiang, both respected experts in materials science, electrochemical systems, and sustainability research. The company has raised more than $140M from leading climate tech investors, strategic investor Siam Cement Group, and cooperative agreements with the U.S. Department of Energy’s ARPA-E, IEDO, and OCED award programs. It currently operates a Somerville, MA-based pilot plant with a >250 TPY production capacity and is developing its 30,000 TPY first commercial facility to open in Holyoke, MA as early as 2026. Learn more at sublime-systems.com.

Media

Erin Glabets

Head of Communications

media@sublime-systems.com

Sublime Systems turned four years old on March 14th. Below is a note our CEO Leah Ellis shared with our investors. We thought it would be an interesting read for the rest of our followers to understand our progress and the road ahead of us!

Dear Sublime Investors, Advisors, and Supporters,

I write you on Sublime’s fourth birthday, grateful for your support, and amazed at what the team at Sublime has accomplished since spinning out of MIT on March 14, 2020. As proud nerds, Yet-Ming Chiang and I were focused on having Pi Day as our founding date, but of course that week would go on to be remembered as the time where virtually everything shut down for the COVID-19 pandemic and we all entered completely uncharted terrain. Thankfully, so much has changed since then, for both the world and Sublime.

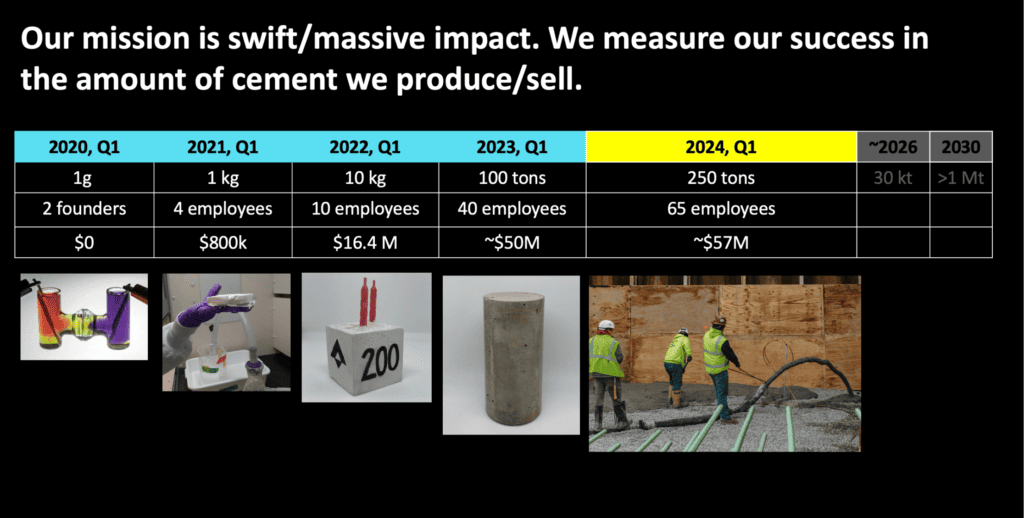

We started Sublime Systems to have a swift and massive impact on global CO2 emissions by decarbonizing cement, the key ingredient in concrete. We measure our success by the amount of cement we produce and ship over time to replace carbon-intensive ordinary portland cement (OPC), the ubiquitous building material whose production is responsible for roughly 8% of global emissions. I’d like to highlight the ways we’ve progressed against this goal in these four fast years.

We developed a breakthrough electrochemical manufacturing process that produces the cement the global construction industry needs but without the emissions. At MIT, Yet and I worked backwards from the understanding that technologies born of the Industrial Revolution’s cheap fossil fuels were ripe for electrification, thanks to a cleaner, greener, increasingly renewable-based grid. We proudly call our process “true zero” because it does not pollute then clean up with net-zero addition and subtraction; it instead uses the elegance of electrochemistry to break down inert feedstocks into their constituent minerals and reactive cementitious ingredients. Because we use a chemical reaction and not heat, we can bypass OPC’s CO2-laden feedstock, limestone, instead using many abundantly available materials with the right ratios of calcium and silicates.

Sublime makes the least expensive, most decarbonized cement because we avoid CO2. Shortly after our founding, we received catalytic capital from Prime Impact Fund Fund (now Azolla Ventures). The U.S. Department of Energy (DOE)‘s ARPA-E program also recognized our potential, awarding us a $0.5 million Small Business Innovation Reasearch (SBIR) grant to validate our technology in the lab, which subsequently allowed us to secure seed funding from The Engine and Lowercarbon Capital. We continue to fine-tune our process in R&D to yield quality cementitious ingredients with low embodied energy. Last year we validated our carbon impact with Climate Earth, the most trusted provider of environmental product declarations (EPDs) for the concrete industry. The preliminary EPD they conducted for us, known as a screening life cycle assessment, demonstrated that our electrochemical manufacturing reduces >90% of the global warming potential of cement manufacturing, compared to a typical EPD for OPC in the U.S. today.

The DoE continues to be a great supporter of our technology and scale up, most recently with a $6.7 million award from its Industrial Efficiency and Decarbonization Office (IEDO). This funding will enable us to develop our process to not just ingest naturally occurring basaltic minerals, but industrial wastes like slags, ashes, and spent concrete. This catalyzes Sublime as not only an ultra-low-carbon manufacturing technology, but a circular one, able to turn the world’s wastes into fresh construction materials that enable us to keep building.

Cement is the biggest industry in the world by mass, and to compete in any meaningful way, we need to rapidly scale to production plants of 1 million tons per year. I often say decarbonized cement is probably the hardest problem any startup founder can take on because of the scale we need to achieve. At our founding, we were producing almond-sized cement samples, at gram scale. In December 2022 we commissioned our pilot plant at Greentown Labs , capable of producing 100 metric tons per year (TPY) of our Sublime Cement™ and shortly after announced our $40 million Series A round to support this scale, with the support of backers such as Lowercarbon Capital, The Engine, Siam Cement Group (SCG), and Energy Impact Partners, and MCJ Collective. In less than a year we more than doubled this pilot capacity to 250 TPY and have run it for over 1,500 hours of operation. We are now shipping the Sublime Cement™ for validation by concrete ready-mix producers around the U.S., working with leading regional innovators to facilitate adoption of our material in their local markets. We have also started engaging our first customers in construction projects (more on that below).

In our relentless focus on scale, we are now actively planning our first commercial manufacturing facility in Holyoke, MA, to open as early as 2026. This 30,000 TPY facility will retire scale-up risk as we swiftly work towards our megaton plant and parity with today’s OPC manufacturing,

While our technology is extraordinary, we want our cement product to feel ordinary and familiar to the experts who place and finish concrete in construction projects. We have worked closely with partners such as BOSTON SAND & GRAVEL CO (BSG), one of the country’s oldest and most trusted ready-mix concrete producers, to tune our product and mix designs to seamlessly integrate into construction infrastructure as a drop-in replacement for OPC in concrete.

We demonstrated this in our first commercial pour, at a Boston site with BSG and Turner Construction Company, the largest domestic contractor in the U.S. Our ASTM C1157-compliant Sublime Cement™ mixed into concrete trucks at BSG’s batch plant, and pumped, poured, placed, and finished, without requiring any new infrastructure or accommodations on the job site. Publicizing our success as a true drop-in replacement has rapidly attracted new interest from customers who are eager to integrate our material into building projects on the frontiers of low-carbon construction. At the same time, customers have reserved over 50% of our future Holyoke capacity with non-binding reservation agreements from organizations spanning construction companies and infrastructure owners.

In 2021 the International Energy Agency (IEA) said 50% of tech needed to reach net-zero didn’t exist commercially. In three years, that number has dropped to 35%. While new carbon avoidance technologies have emerged, many are not yet at a commercial scale. The DoE has stepped up to fill this gap, by funding its DOE Office of Clean Energy Demonstrations (OCED). Sublime has applied for this catalytic financing and remains hopeful about our chances.

The public sector has in many other ways embraced its role in cement’s decarbonization. It is fitting that it does so, as the public sector purchases over 50% of the cement used in the USA and is by far the single-largest buyer of this material. A recently introduced, bipartisan bill called the Concrete and Asphalt Innovation Act includes a provision that would allow federal agencies to sign advance market commitments (AMCs) for low-carbon materials up to three years before they are ready, unleashing an important buyer signal to the types of private investors we’d need for future scale up. Sublime has advocated for policies like this through the Decarbonized Cement & Concrete Alliance (DC2), an organization we co-founded that coalesces like-minded startups.

Cement has carried us from the Roman times to our modern world. Our team gets up for work every day because we want to make the cement that brings us to our post-carbon future. OPC production is a 200-year-old process that is begging for reinvention. The telephone was invented more than 50 years after OPC!

I am so grateful for the team, investors, advisors, and community that share our mission for decarbonizing cement and addressing the world’s single biggest source of industrial emissions. 2050 is hurtling towards us, but I am hopeful when I see the energy of our community and the progress we have made. There is by no means an easy road ahead, but we aren’t doing this because it’s easy. We are doing it because the world needs it.

Thank you for all your support. We’ll Keep Building!!

Leah

This website was designed and built sustainably 🌱.

© 2024 Sublime Systems. All rights reserved.