Sublime’s breakthrough clean manufacturing process makes Sublime Cement that replaces OPC in concrete with inherent advantages in durability, color, and consistency.

We electrochemically extract reactive calcium, silicates, and other ingredients from an abundant feedstocks and blend these into an ASTM-compliant Sublime Cement. This recipe is inspired by Roman cement, which can still be experienced in enduring structures like the Colosseum today.

Our fully electrified manufacturing avoids the emissions, waste, and inherent impurities from limestone and combustion. The result is a Sublime Cement® that can outperform legacy portland cements and outpace the alternatives for cleaning up concrete emissions.

Our fully electrified manufacturing avoids the emissions, waste, and inherent impurities from limestone and combustion, producing Sublime Cement that can outperform legacy portland cements and outpace the alternatives for cleaning up concrete emissions.

Alkali-Silica Reaction (ASTM C1260/C1239, AASHTO T380)

Much better

Rapid Chloride Permeability Test (RCPT) (ASTM C1202)

Much better

Electrical Surface Resistivity (AASHTO T358)

Much better

Drying Shrinkage of Concrete (ASTM C157)

Better

Sulfate Attack (ASTM C1012)

Better

Freeze-thaw resistance (ASTM C666)

Equivalent

Outperforms OPC across most key durability characteristics for longer-lasting, more reliable concrete.

Clean, combustion-free manufacturing can yield lighter color cement, which has aesthetic and heat reflectivity premium benefits.

Precision engineered, electrochemical process avoids kiln and limestone impurities, reducing the batch-to-batch variability that hampers OPC performance and drives overdesign in concrete mixes.

Replaces OPC in concrete with similar mix designs and admixtures and uses the industry’s existing equipment, operations, and processes on the construction site for smooth adoption.

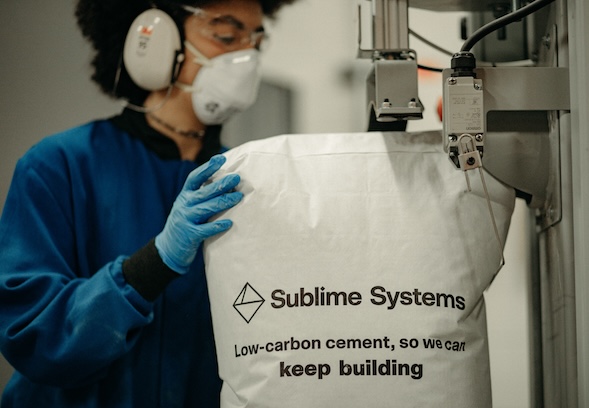

We’ve secured critical third-party validations demonstrating our performance, safety, and emissions reduction impact.

American Engineering Testing ensured our product meets ASTM C1157, the standard performance specification for hydraulic cement.

Our Safety Data Sheets ensure our product complies with OSHA’s Hazard Communication Standard 29CFR1910.1200 and can be safely handled just like the cement the world is used to.

Climate Earth completed our screening life cycle assessment (LCA), validating our process’ path to a 90% reduction in cement’s global warming potential.

The global construction industry is high integrity and rightfully committed to the safety and performance of their materials. We’re meeting the industry where they are, by diligently testing and advancing our material for a smooth path from the lab to the construction site.

We’ve secured critical third-party validations demonstrating our performance, safety, and emissions reduction impact.

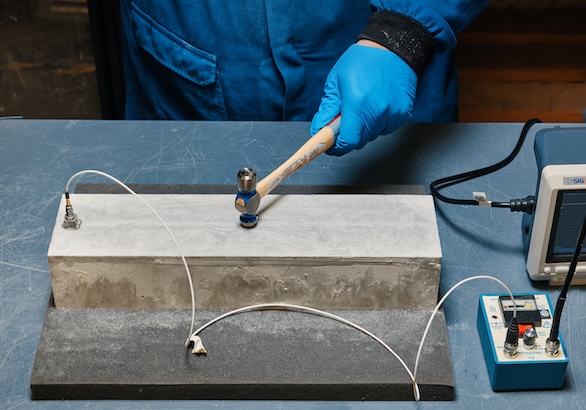

Calorimetry tests heat of hydration, indicators of early-age behavior and strength development.

We test for the concrete’s fresh and hardened durability properties.

Regional ready-mix leaders test our cement’s performance in their concrete mixes .

This culminates in field construction projects, where our material is mixed at the batching plant, transported in ready-mix trucks, pumped, placed, and finished into a final hardened concrete slab.

We test for flowability, compressive strength, and admixture compatibility.

External, ASTM-validated labs test our material across strength and durability parameters.

and finish when placed by concrete contractors.

We produce Sublime Cement out of our 250 TPY pilot facility in Somerville, MA and are developing our first commercial kiloton facility to open in Holyoke, MA. Inquire about partnering today around a testing deployment or reserving Sublime Cement produced out of Holyoke, for a clean, durable, American-made material to future-proof your supply chain.