Upcoming Notification for Sublime Users - Click Here

Upcoming Notification for Sublime Users - Click Here

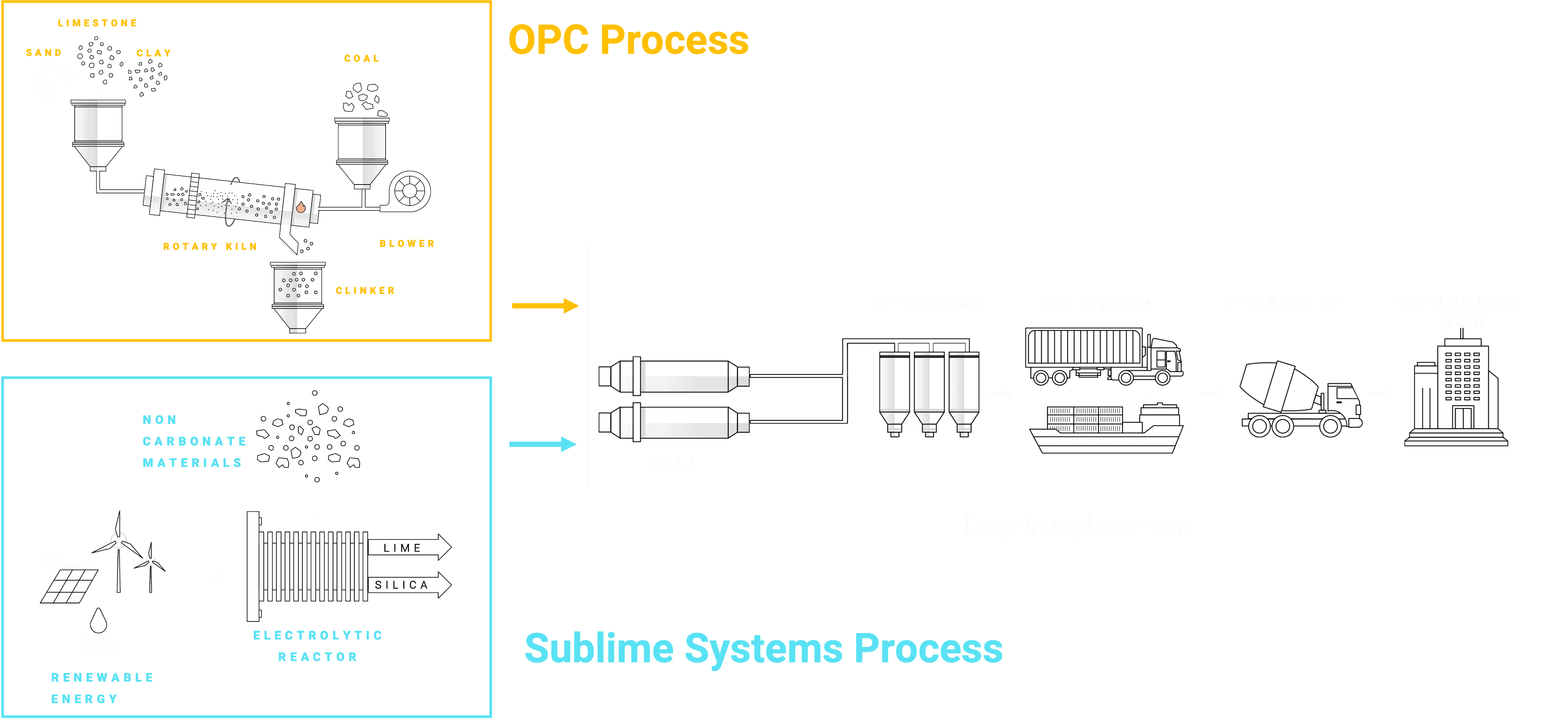

Today’s portland cement is made by cooking limestone, sand, and clay in massive fossil-fueled 1450°C kilns. This results in a tremendous amount of CO₂: on average 0.9 tonnes per tonne of OPC in the USA. About half of this CO₂ is released from limestone, which is ~50% by weight CO₂, as it decomposes in the kiln to form reactive lime. The other half of the CO₂ emissions is from the fossil fuel (often bituminous coal) needed to reach 1450°C, the temperature required to form the crystal structure characteristic of OPC. This temperature is currently impossible to electrify efficiently.

We skip both emissions sources, instead using the elegance of electrochemistry to extract reactive calcium (Sublime Lime™) and silicates from abundant raw materials that are then blended into a final Sublime Cement™. Our cement’s crystal structure is different than the OPC produced in a fiery kiln, but its performance and hardened phase in concrete are the same.

Our process decarbonizes cement production by avoiding CO₂ emissions in the first place. We skip the carbon addition and subtraction typical of net-zero solutions — and the associated expense and complexity of carbon capture, sequestration, credits, and clean up.

Our process transforms electrical energy into chemical energy to break feedstocks down into their constituent elements. We then reassemble these pure, reactive ingredients into the ideal cement composition. We use every part of the rock, leading to near-zero waste, unlike the limestone mined for OPC, 50% of which ends up as greenhouse gas emissions or otherwise wasted.

Sublime CementTM

>90% CO₂ Reduction Possible

Cost

Meets Ready-Mix Specs

Fossil Fuel Use

Embodied Energy

Cement today (OPC)

>90% CO₂ Reduction Possible

Cost

Meets Ready-Mix Specs

Fossil Fuel Use

Embodied Energy

OPC + Carbon Capture

>90% CO₂ Reduction Possible

Cost

Meets Ready-Mix Specs

Fossil Fuel Use

Embodied Energy

Supplementary Cementitious Materials

>90% CO₂ Reduction Possible

Cost

Meets Ready-Mix Specs

Fossil Fuel Use

Embodied Energy

Carbonated / CO₂-Cured

>90% CO₂ Reduction Possible

Cost

Meets Ready-Mix Specs

Fossil Fuel Use

Embodied Energy

We replace carbon-intensive limestone with calcium silicate minerals or industrial wastes.

We use electricity, not heat, to break down feedstocks into their constituent minerals.

This intrinsically purifying process extracts all the individual minerals from the rock, including iron oxide and magnesium hydroxide —providing a cleaner, cheaper source of these materials that are critical for many industrial applications today.

Calcium and silicates are produced from this process as the essential, reactive ingredients for cement.

The final result is an ASTM C1157 Sublime Cement™ to displace OPC.

This intrinsically purifying process extracts all the individual minerals from the rock, including iron oxide and magnesium hydroxide —providing a cleaner, cheaper source of these materials that are critical for many industrial applications today.

Sublime was invented because the proliferation of renewable energy meant that the fossil-fueled processes of the Industrial Revolution could finally be electrified. While many decarbonization technologies are working to access this clean grid electricity, Sublime’s manufacturing has the highest impact. Each kWh displaces limestone emissions (the majority emissions from traditional cement-making) and the energy emissions from coal-fired kilns.

The mass of man-made things now exceeds the mass of living things on earth — and half of that mass is concrete. To preserve the health of ecosystems and biodiversity, we must avoid both carbon emissions and waste. Our Sublime™ electrochemical process can be adapted to produce Sublime Lime™, silicates, and cementitious ingredients from a range of both naturally occurring minerals and many industrial wastes that are currently landfilled. This spans slag byproducts from steelmaking, kiln ashes and dusts, and even returned and demolished concrete.

Corporate

Sublime Systems

28 Park Street

Somerville, MA 02143

Contact

info@sublime-systems.com

+1 617 831 4328

LinkedIn

This website was designed and built sustainably 🌱.

© 2024 Sublime Systems. All rights reserved.