Sublime Systems turned four years old on March 14th. Below is a note our CEO Leah Ellis shared with our investors. We thought it would be an interesting read for the rest of our followers to understand our progress and the road ahead of us!

Dear Sublime Investors, Advisors, and Supporters,

I write you on Sublime’s fourth birthday, grateful for your support, and amazed at what the team at Sublime has accomplished since spinning out of MIT on March 14, 2020. As proud nerds, Yet-Ming Chiang and I were focused on having Pi Day as our founding date, but of course that week would go on to be remembered as the time where virtually everything shut down for the COVID-19 pandemic and we all entered completely uncharted terrain. Thankfully, so much has changed since then, for both the world and Sublime.

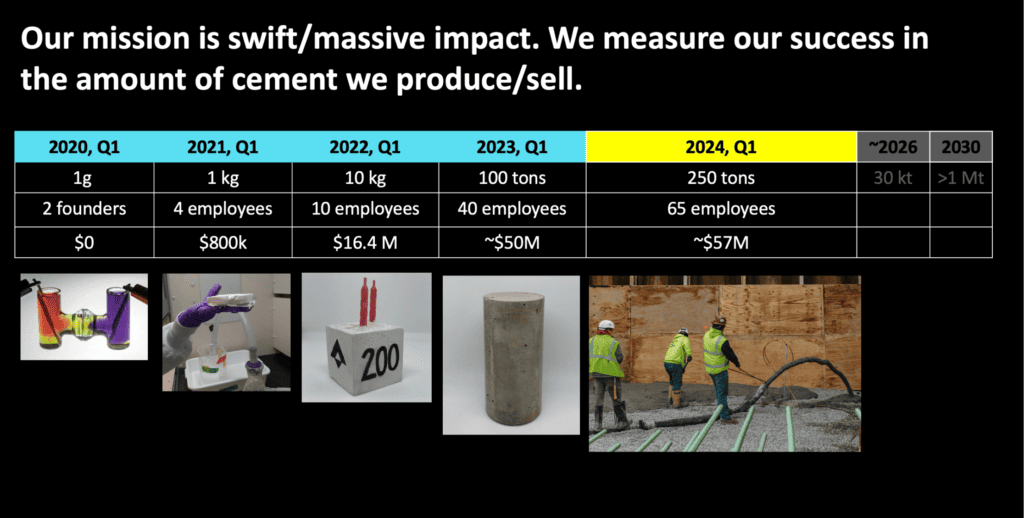

We started Sublime Systems to have a swift and massive impact on global CO2 emissions by decarbonizing cement, the key ingredient in concrete. We measure our success by the amount of cement we produce and ship over time to replace carbon-intensive ordinary portland cement (OPC), the ubiquitous building material whose production is responsible for roughly 8% of global emissions. I’d like to highlight the ways we’ve progressed against this goal in these four fast years.

We have invented the leading technology for avoiding cement manufacturing emissions

We developed a breakthrough electrochemical manufacturing process that produces the cement the global construction industry needs but without the emissions. At MIT, Yet and I worked backwards from the understanding that technologies born of the Industrial Revolution’s cheap fossil fuels were ripe for electrification, thanks to a cleaner, greener, increasingly renewable-based grid. We proudly call our process “true zero” because it does not pollute then clean up with net-zero addition and subtraction; it instead uses the elegance of electrochemistry to break down inert feedstocks into their constituent minerals and reactive cementitious ingredients. Because we use a chemical reaction and not heat, we can bypass OPC’s CO2-laden feedstock, limestone, instead using many abundantly available materials with the right ratios of calcium and silicates.

Sublime makes the least expensive, most decarbonized cement because we avoid CO2. Shortly after our founding, we received catalytic capital from Prime Impact Fund Fund (now Azolla Ventures). The U.S. Department of Energy (DOE)‘s ARPA-E program also recognized our potential, awarding us a $0.5 million Small Business Innovation Reasearch (SBIR) grant to validate our technology in the lab, which subsequently allowed us to secure seed funding from The Engine and Lowercarbon Capital. We continue to fine-tune our process in R&D to yield quality cementitious ingredients with low embodied energy. Last year we validated our carbon impact with Climate Earth, the most trusted provider of environmental product declarations (EPDs) for the concrete industry. The preliminary EPD they conducted for us, known as a screening life cycle assessment, demonstrated that our electrochemical manufacturing reduces >90% of the global warming potential of cement manufacturing, compared to a typical EPD for OPC in the U.S. today.

The DoE continues to be a great supporter of our technology and scale up, most recently with a $6.7 million award from its Industrial Efficiency and Decarbonization Office (IEDO). This funding will enable us to develop our process to not just ingest naturally occurring basaltic minerals, but industrial wastes like slags, ashes, and spent concrete. This catalyzes Sublime as not only an ultra-low-carbon manufacturing technology, but a circular one, able to turn the world’s wastes into fresh construction materials that enable us to keep building.

We have scaled rapidly in 4 short years

Cement is the biggest industry in the world by mass, and to compete in any meaningful way, we need to rapidly scale to production plants of 1 million tons per year. I often say decarbonized cement is probably the hardest problem any startup founder can take on because of the scale we need to achieve. At our founding, we were producing almond-sized cement samples, at gram scale. In December 2022 we commissioned our pilot plant at Greentown Labs , capable of producing 100 metric tons per year (TPY) of our Sublime Cement™ and shortly after announced our $40 million Series A round to support this scale, with the support of backers such as Lowercarbon Capital, The Engine, Siam Cement Group (SCG), and Energy Impact Partners, and MCJ Collective. In less than a year we more than doubled this pilot capacity to 250 TPY and have run it for over 1,500 hours of operation. We are now shipping the Sublime Cement™ for validation by concrete ready-mix producers around the U.S., working with leading regional innovators to facilitate adoption of our material in their local markets. We have also started engaging our first customers in construction projects (more on that below).

In our relentless focus on scale, we are now actively planning our first commercial manufacturing facility in Holyoke, MA, to open as early as 2026. This 30,000 TPY facility will retire scale-up risk as we swiftly work towards our megaton plant and parity with today’s OPC manufacturing,

We have gained enthusiastic collaborators and customers across the entire construction value chain

While our technology is extraordinary, we want our cement product to feel ordinary and familiar to the experts who place and finish concrete in construction projects. We have worked closely with partners such as BOSTON SAND & GRAVEL CO (BSG), one of the country’s oldest and most trusted ready-mix concrete producers, to tune our product and mix designs to seamlessly integrate into construction infrastructure as a drop-in replacement for OPC in concrete.

We demonstrated this in our first commercial pour, at a Boston site with BSG and Turner Construction Company, the largest domestic contractor in the U.S. Our ASTM C1157-compliant Sublime Cement™ mixed into concrete trucks at BSG’s batch plant, and pumped, poured, placed, and finished, without requiring any new infrastructure or accommodations on the job site. Publicizing our success as a true drop-in replacement has rapidly attracted new interest from customers who are eager to integrate our material into building projects on the frontiers of low-carbon construction. At the same time, customers have reserved over 50% of our future Holyoke capacity with non-binding reservation agreements from organizations spanning construction companies and infrastructure owners.

The U.S. public sector is embracing its role in cement decarbonization

In 2021 the International Energy Agency (IEA) said 50% of tech needed to reach net-zero didn’t exist commercially. In three years, that number has dropped to 35%. While new carbon avoidance technologies have emerged, many are not yet at a commercial scale. The DoE has stepped up to fill this gap, by funding its DOE Office of Clean Energy Demonstrations (OCED). Sublime has applied for this catalytic financing and remains hopeful about our chances.

The public sector has in many other ways embraced its role in cement’s decarbonization. It is fitting that it does so, as the public sector purchases over 50% of the cement used in the USA and is by far the single-largest buyer of this material. A recently introduced, bipartisan bill called the Concrete and Asphalt Innovation Act includes a provision that would allow federal agencies to sign advance market commitments (AMCs) for low-carbon materials up to three years before they are ready, unleashing an important buyer signal to the types of private investors we’d need for future scale up. Sublime has advocated for policies like this through the Decarbonized Cement & Concrete Alliance (DC2), an organization we co-founded that coalesces like-minded startups.

We are building for our post-carbon future

Cement has carried us from the Roman times to our modern world. Our team gets up for work every day because we want to make the cement that brings us to our post-carbon future. OPC production is a 200-year-old process that is begging for reinvention. The telephone was invented more than 50 years after OPC!

I am so grateful for the team, investors, advisors, and community that share our mission for decarbonizing cement and addressing the world’s single biggest source of industrial emissions. 2050 is hurtling towards us, but I am hopeful when I see the energy of our community and the progress we have made. There is by no means an easy road ahead, but we aren’t doing this because it’s easy. We are doing it because the world needs it.

Thank you for all your support. We’ll Keep Building!!

Leah